SSI Consulting, now IMEG is your partner for successful grain industry projects. Visit us at booth 1633 at the Grain Elevator and Processing Society (GEAPS) Exchange 2025, the largest event in the grain industry, on Sunday, February 23 - Tuesday, February 25.

Read MoreAeration is a critical practice in industries that handle finely ground, powdery substances such as cement, raw meal, and lime. By introducing air into silos, these materials can be fluidized to enhance their flow from storage spaces. However, this process requires careful consideration of various factors, including the slope of the silo bottom, the pressure of the aeration air, and the potential for material caking. Explore the intricacies of silo aeration, common challenges, and the importance of engineering analyses to ensure safe and efficient material reclaim.

Read MoreExplore the impact of aeration-assisted discharge in large cylindrical silos equipped with inverted conical hoppers, commonly used for storing fine dry powders like cement. These silos often suffer structural damage due to overstress from circumferential flexure and tension. The primary cause of this damage is identified as the formation of asymmetric flow channels at the silo wall, resulting from discharge openings’ proximity to the wall and aeration pressure.

Read More

Explore the key elements of successful grain material handling with Gerry Lynskey, a seasoned Professional Engineer. In this blog, discover the importance of material selection, engineering design for efficiency, the integration of automation and monitoring systems, and more.

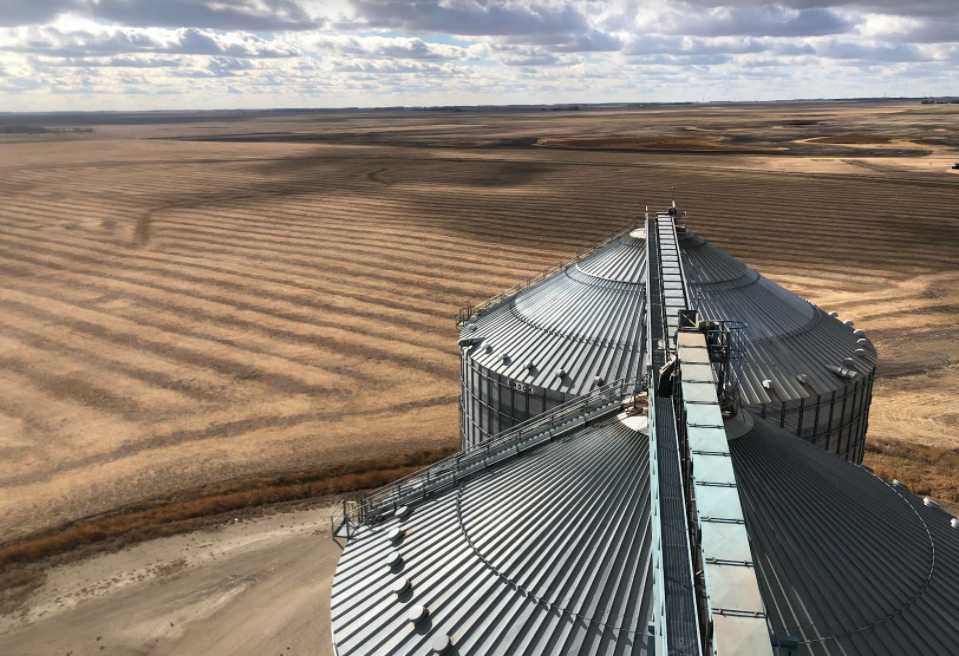

Read MoreIf you’re ready to talk best practices in grain handling, milling facility engineering design, and silo inspection, SSI is your partner for long-term success. Learn more about how SSI delivers affordable solutions to your biggest grain industry challenges with more than 100 collective years of experience.

Read MoreLooking for affordable solutions to the industry’s biggest grain handling, engineering design, and silo inspection challenges? Learn how SSI Consulting works as a true partner, bringing more than 100 collective years of experience to your projects.

Read MoreIf you’re ready to talk best practices in grain handling, milling facility engineering design, and silo inspection, SSI is your partner for long-term success. Learn more about how SSI delivers affordable solutions to your biggest grain industry challenges with more than 100 collective years of experience.

Read MoreDiscover 5 silo hacks to help you identify potential challenges, so you can keep your products flowing and your facilities safe.

Read MoreWe are excited to connect with you at #GEAPS Exchange 2021: Aug 6-9, in Columbus, OH! We’re looking forward to sharing our grain industry expertise with you. Visit our team at booth 326 and attend our best practices presentation.

Read MoreAccording to our extensive experience, two out of three facilities have silos with serious issues that should be repaired. And, without a full inspection the risk is often not detected until it’s too late. Learn more about inspections inside the silo in this blog.

Read MoreWhile traveling has been at a stand-still for many people, the SSI team is living on the edge. They are out in the field building, designing and repairing structures all over the country. SSI’s team of dedicated engineering and design professionals scales walls, conducts inspections, and designs projects to keep industrial facilities running across the country.

Read MoreWhen silo walls are overstressed what are the options? This blog will explore best practice solutions for silo repair.

Read MoreMany blending and homogenizing silos are structurally deficient. Explore the most common challenges and solutions in silo engineering design from industry experts.

Read MoreLearn about options available for silo wall repair, from carbon fiber sheet reinforcement to shotcrete/gunnite reinforced liners.

Read More